Current location:Home > Hebei Hankai 25 47 7 oil seal >

Hebei Hankai 25 47 7 oil seal

2025-08-14 18:17

2025-08-14 18:10

2025-08-14 17:40

2025-08-14 17:30

2025-08-14 17:05

2025-08-14 16:41

2025-08-14 16:41

2025-08-14 16:36

2025-08-14 16:30

2025-08-14 16:25

Latest articles

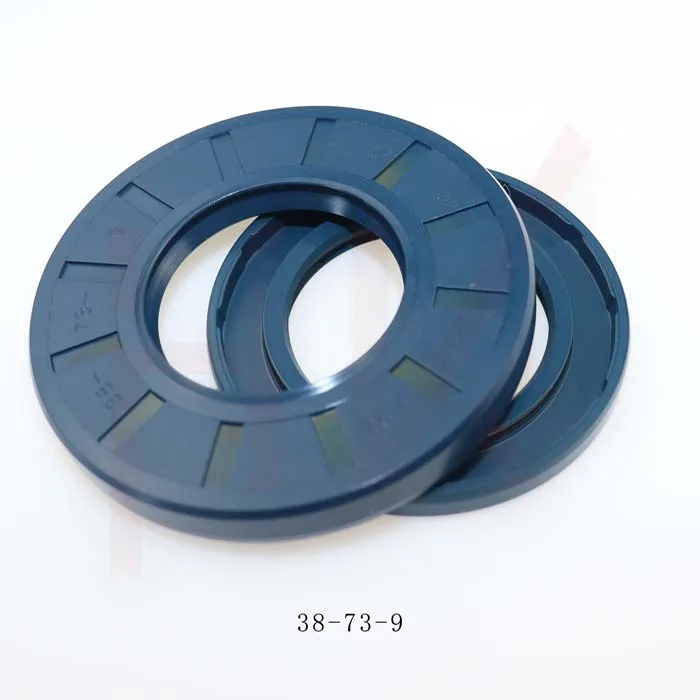

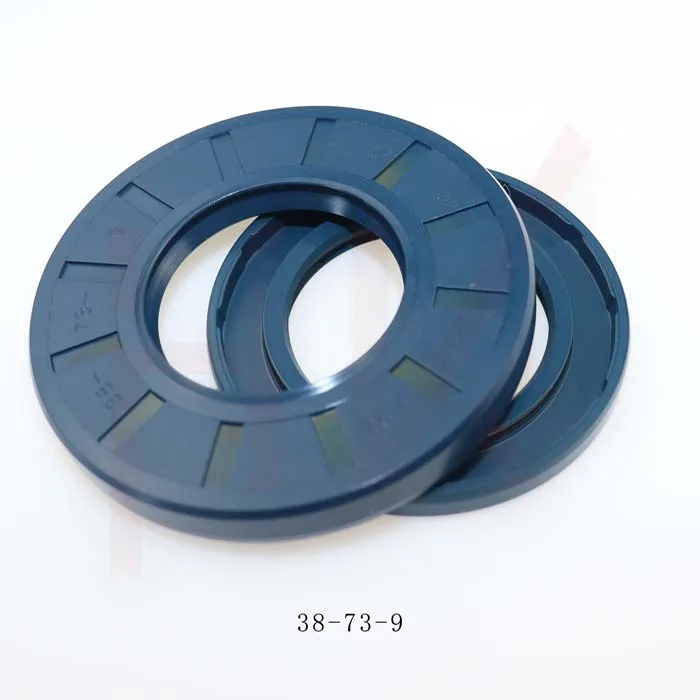

One common type of oil seal is the lip seal, which features a flexible lip that makes contact with the rotating shaft to create a tight seal. Lip seals are often used in automotive engines, gearboxes, and industrial pumps due to their effectiveness in preventing oil leaks. Another popular option is the mechanical seal, which uses a rotating element to maintain constant contact with the shaft, ensuring a reliable seal even at high speeds and pressures.

20 30 7 oil seal

Rotary shaft oil seals come in a variety of designs and materials to suit different applications and environments. Common materials used in the construction of oil seals include rubber, silicone, polyurethane, and fluorocarbon. Each material has its own unique properties that make it suitable for specific operating conditions, such as high temperatures, high pressures, or exposure to harsh chemicals.

Replacing hydraulic seals is a task that requires precision and attention to detail. It is important to use the correct replacement seals that are compatible with the specific hydraulic system. The first step is to identify the type and size of the seals that need to be replaced. This information can usually be found in the equipment manual or by consulting with a hydraulic system specialist

hydraulic seal replacement.

hydraulic seal replacement.

One of the advantages of using pretty tomato cages is that they come in different sizes and shapes to accommodate your tomato plants. Whether you have cherry tomatoes or beefsteak tomatoes, there is a cage that can provide the necessary support for your plants to thrive. Additionally, these cages are durable and long-lasting, ensuring that your tomato plants are well-supported throughout the growing season.

1 adjustable compression spring. Manufacturing In manufacturing processes, adjustable compression springs are used to apply consistent force during assembly lines, ensuring that components are properly aligned and secured.

adjustable compression spring. Manufacturing In manufacturing processes, adjustable compression springs are used to apply consistent force during assembly lines, ensuring that components are properly aligned and secured.

adjustable compression spring. Manufacturing In manufacturing processes, adjustable compression springs are used to apply consistent force during assembly lines, ensuring that components are properly aligned and secured.

adjustable compression spring. Manufacturing In manufacturing processes, adjustable compression springs are used to apply consistent force during assembly lines, ensuring that components are properly aligned and secured.